As an avid researcher, I have recently delved into the world of liquid silicone rubber products and their impact on sustainability in the supply chain. These versatile materials offer a wide range of applications and benefits that make them an excellent choice for various industries.

The Versatility of Liquid Silicone Rubber Products

Liquid silicone rubber (LSR) products are highly flexible and durable materials that can be molded into complex shapes with precision. They possess excellent thermal stability, chemical resistance, and electrical insulation properties, making them suitable for a diverse range of applications.

From automotive parts to consumer electronics, LSR products find their use in numerous industries. Their ability to withstand extreme temperatures without compromising performance makes them ideal for manufacturing components used in harsh environments.

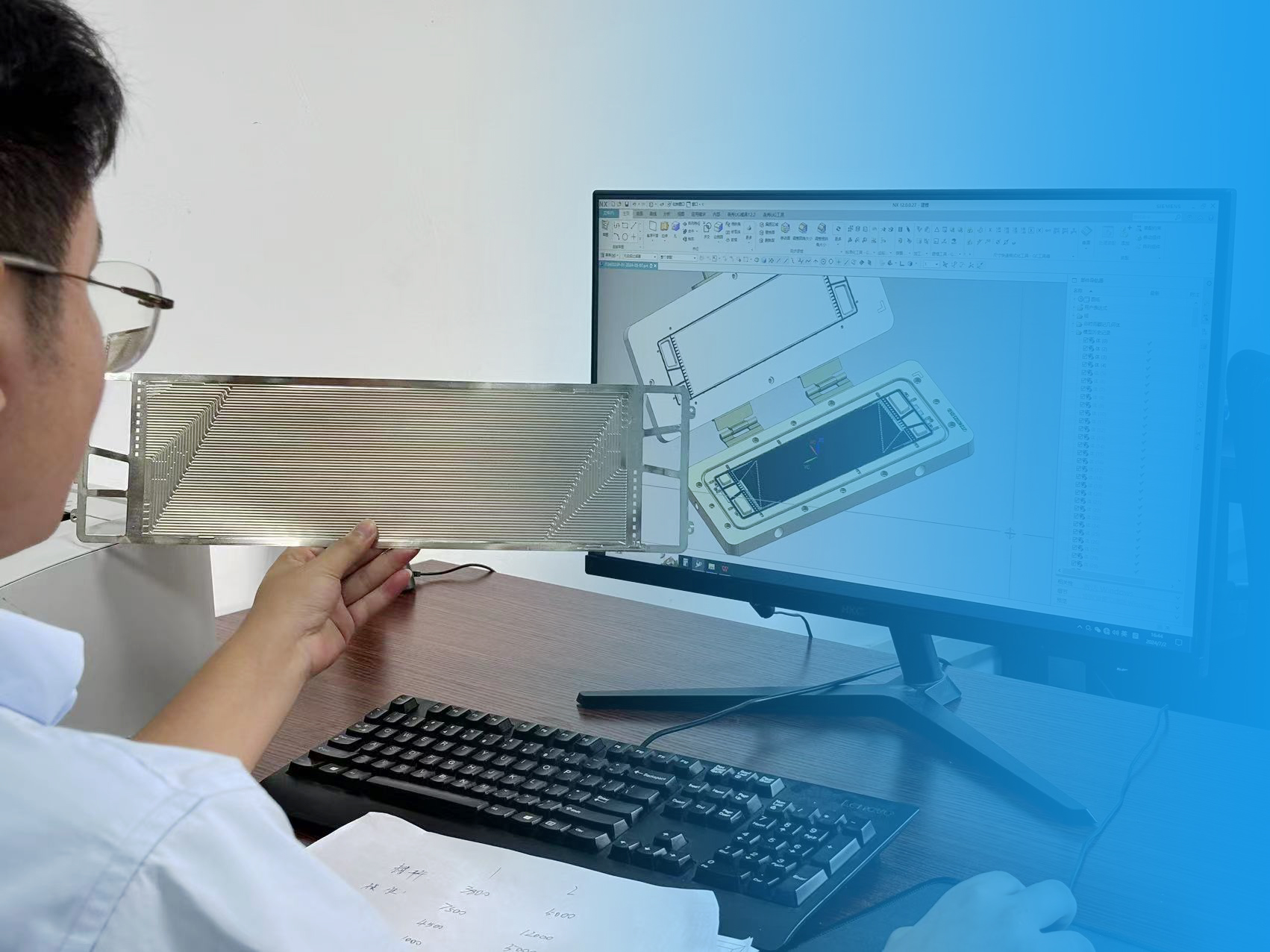

JVTECH: Pioneering Innovation in LSR Technology

One company at the forefront of developing cutting-edge liquid silicone rubber solutions is JVTECH. With their expertise in material science and engineering, they have revolutionized the industry by introducing advanced manufacturing techniques that enhance product quality while reducing environmental impact.

By leveraging state-of-the-art machinery and automation processes, JVTECH ensures precise control over every stage of production. This not only improves efficiency but also minimizes waste generation during manufacturing operations.

The Advantages of Medical Grade LSR

A specific application where liquid silicone rubber truly shines is in medical devices. medical grade lsr offers exceptional biocompatibility, meaning it does not cause adverse reactions when it comes into contact with human tissue or bodily fluids.

This high level of purity makes medical grade LSR an ideal choice for producing implants such as pacemaker leads or catheters. Its flexibility allows these devices to conform to the body’s contours, ensuring patient comfort and reducing the risk of complications.

Furthermore, medical grade LSR is resistant to bacteria growth and can be easily sterilized, making it a reliable material for critical healthcare applications.

The Sustainable Future with Liquid Silicone Rubber Products

Liquid silicone rubber products offer numerous sustainability benefits throughout the supply chain. Their durability and longevity reduce the need for frequent replacements, resulting in less waste generation. Additionally, their energy-efficient manufacturing processes contribute to lower carbon emissions.

Moreover, as liquid silicone rubber is a recyclable material, end-of-life products can be repurposed or recycled into new components rather than ending up in landfills. This circular approach promotes resource conservation and reduces environmental impact.

In conclusion, liquid silicone rubber products have emerged as a sustainable solution within the supply chain due to their versatility, innovative manufacturing techniques employed by companies like JVTECH, and specific applications such as medical grade LSR. By embracing these materials and practices that prioritize sustainability, we can pave the way for a greener future while meeting industry demands effectively.